JC Series

Advanced blast chiller

New design, new functions and a very user friendly display are the main features of the new JC series, developed to satisfy customer needs, both from the handmade and industrial sector. The JolyIce experience grant new functions to these models.

The advanced blast chiller

Blast Chiller

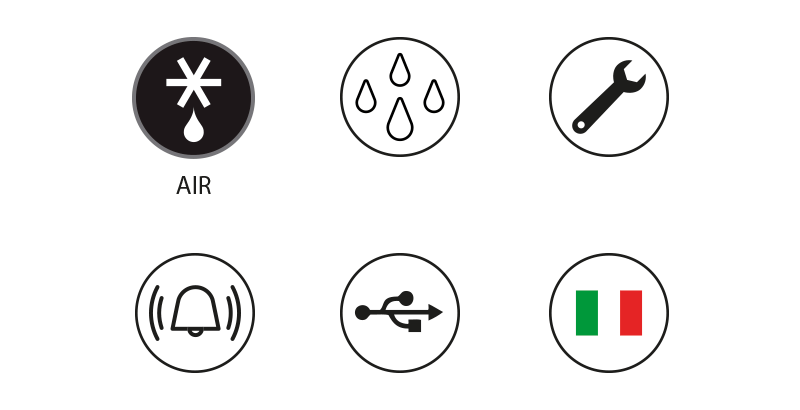

The most advanced blast chiller solutions in order to ensure quality and hygiene in food processing.

Thawing

Thawing by controlled temperature and humidity.

Icecream

A specific and dedicated function for ice cream, in all the product range.

Chilling programs

A wide range of chilling programs, always at your service.

HACCP control

Cycles details can be easily stored on an USB stick, in compliance with HACCP guidelines.

Sanification

The highest hygene levels are guaranteed by an Ozone sterilizer.

Utilities

Drying

Drying cycle through forced ventilation.

Hot gas defrosting

Possibility to launch a manual hot gas defrosting.

Service

Easier access to all service utilities.

Alarms

Possibility to see active and previous alarm lists.

Data storage

It’s possible to download the full alarm list and the cycle details, through the USB stick.

Languages

Possibility to set the language.

Condensate collecting pan

Easy to pull out and to empty, for simple installation in places without any water draining.

Evaporator

Evaporator easy to inspect and with hot gas defrosting, painted in order to avoid corrosion risk. Indirect air flow.

Dual suitability trays rack

Easily removable for cleaning, it is designed to facilitate the chilling air flow, increasing the machine efficiency. Suitable for both GN1/1 and EN 600 x 400 mm trays

Core probe

Automatically controls the length of the blast chilling cycle; conic shaped, can be easily removed after the cycle, no heating needed. The double probe is available as an option.

Internal floor

Pressed internal floor to guarantee an easy cleaning and maximum hygiene.

Cabinets Body

Cabinet internal and external in stainless steel, made by injected polyurethane without CFC. Thickness 70 mm. Internal rounded corners.

Reversible door

Reversible door and with self-closing system for angles of less than 90°.

Door handles: the innovative design, ergonomic and simple to clean, make easy and safe the door opening and closing.

USB recorder (optional)

To store date, temperarature, cycles timing and alarms.

Ozone Sanification (optional)

Sanitizes the blast chilling chamber after cleaning the machine. Useful also for sanitize working tools.